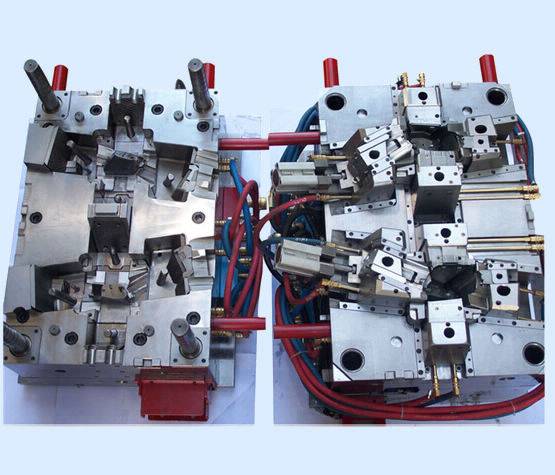

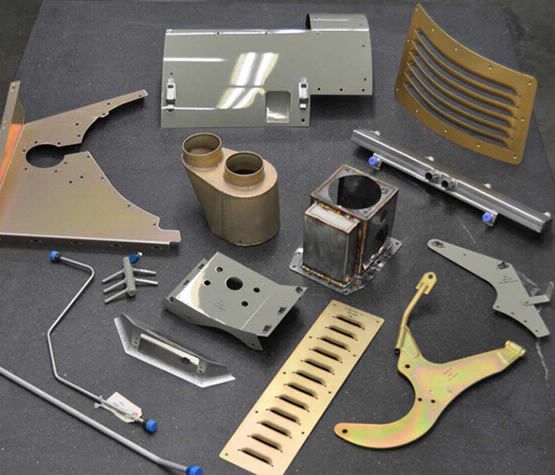

Precision Machined Parts

CNC machining is an economical process to produce rapid prototypes in China. As an outstanding CNC prototyping China factory, we're good at manufacturing high precision metal machined parts and quality plastic prototypes to serve various industries, such as medical devices, motorcycle, automotive, optical communication, electronics, sporting equipment, injection molding and machinery.

The metal prototypes can be made of a wide range of steels, which include copper, 17-7 PH, stainless steel, titanium, carbon steel, aluminium, nickel alloys, brass, bronze, etc.